Ọna kalẹnda ilẹ PVC jẹ imudara ati ilana iṣelọpọ lemọlemọfún, eyiti o dara ni pataki fun iṣelọpọ isokan ati awọn iwe igbekalẹ igbekalẹ (gẹgẹbi ilẹ ilẹ isokan isokan ti iṣowo). Ohun pataki rẹ ni lati ṣe pilasitik PVC didà sinu Layer tinrin aṣọ kan nipasẹ calender olona-yipo, ati lẹhinna tutu lati ṣe apẹrẹ. Awọn atẹle jẹ awọn igbesẹ kan pato ati awọn aaye iṣakoso imọ-ẹrọ bọtini:

I. Ilana Kalẹnda

Itọju Ohun elo Raw> Dapọ gbigbona iyara to gaju, itutu agbaiye ati dapọ tutu, dapọ inu ati ṣiṣu, dapọ ṣiṣi ati ifunni

Kalẹnda-eerun mẹrin, embossing/laminating, itutu agbaiye ati apẹrẹ, gige ati yikaka

II. Igbesẹ-nipasẹ-Igbese Awọn aaye bọtini Iṣiṣẹ ati Awọn paramita Imọ-ẹrọ

1. Aise ohun elo Pretreatment ati dapọ

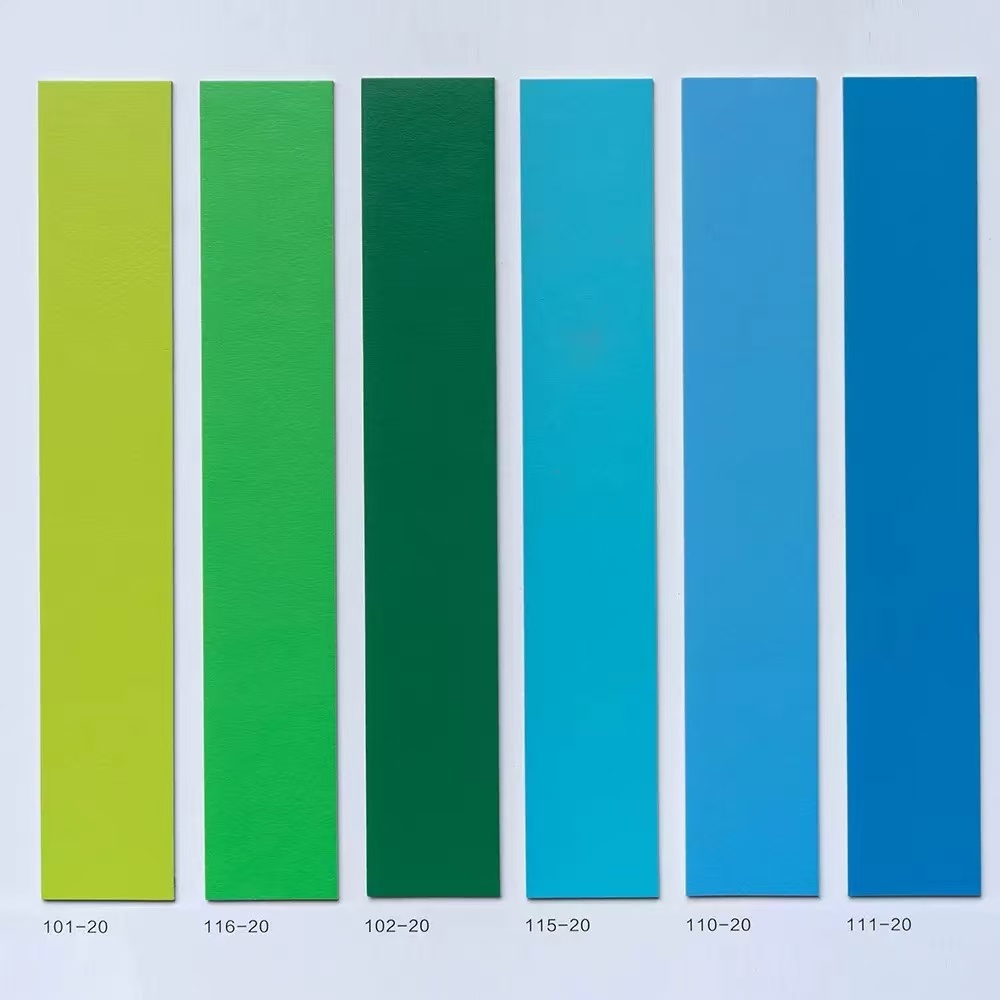

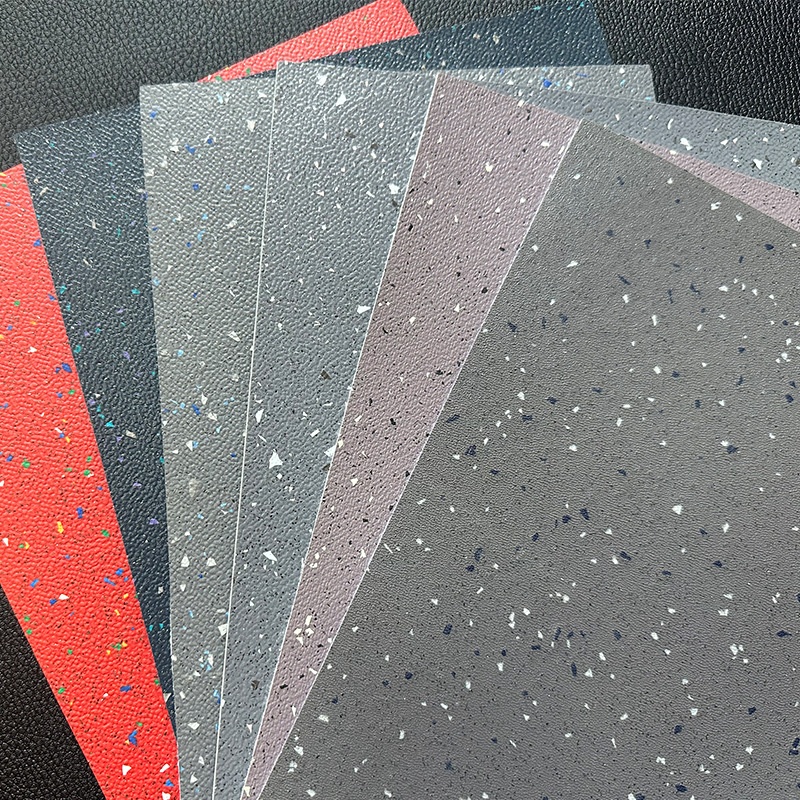

Ilana agbekalẹ (Apeere): - PVC resini (S-70 iru) 100 awọn ẹya ara, - Plasticizer (DINP / ayika ore ester) 40-60 awọn ẹya ara, - Calcium carbonate filler (1250 apapo) 50-80 awọn ẹya ara, - Heat amuduro (calcium zinc composite), - 3-5 stetti acid part - Pigmenti (titaniji oloro / inorganic awọ lulú) 2-10 awọn ẹya ara

Ilana idapọ*:

Iparapọ gbigbona: Alapọpo iyara to gaju (≥1000 rpm), ooru si 120 ° C (iṣẹju 10-15) lati gba PVC laaye lati fa ṣiṣu; Idapọ tutu: Ni kiakia dara si isalẹ 40°C (lati dena awọn lumps), akoko dapọ tutu ≤ 8 iṣẹju.

2. Plasticizing ati ono

- Alapọpo inu: Iwọn otutu 160-170 ° C, Ipa 12-15 MPa, Aago 4-6 iṣẹju → Ṣiṣẹda ọpọn roba isokan;

Ṣi i Mixer: Twin-roll otutu 165± 5°C, Roller Gap 3-5 mm → Ge sinu awọn ila fun ifunni lemọlemọ si calender.

3. Kalẹnda oni rola mẹrin (Ilana mojuto)

- Awọn ọna ẹrọ bọtini:

- Roller Speed Ratio: 1 #: 2 #: 3 #: 4 # = 1: 1.1: 1.05: 1.0 (lati dena ikojọpọ ohun elo);

- Biinu-Iga-arin: Roller 2 jẹ apẹrẹ pẹlu ade 0.02-0.05mm kan lati ṣe aiṣedeede abuku atunse igbona. 4. Dada Itoju ati Lamination

Embossing: embossing roller (silikoni / irin) otutu 140-150 ° C, titẹ 0.5-1.0 MPa, iyara ti o baamu si laini calendering;

Sobusitireti Lamination (Eyi je ko): Gilasi okun akete/ti kii-hun fabric, preheated (100°C), ti wa ni laminated pẹlu awọn PVC yo ni rola #3 lati jẹki onisẹpo iduroṣinṣin.

5. Itutu ati Apẹrẹ

Iwọn otutu itutu agbaiye mẹta:

Iṣakoso ẹdọfu: Yiyi ẹdọfu 10-15 N/mm² (lati ṣe idiwọ isunki tutu ati abuku).

6. Trimming ati Yiyi

- Iwọn wiwọn Sisanra lori ayelujara: Awọn esi gidi-akoko ṣatunṣe aafo rola (ipe ± 0.01mm);

- Gige adaṣe laifọwọyi: iwọn alokuirin ≤ 20mm, tunlo ati pelletized fun ilotunlo;

- Yiyi: Ibakan ẹdọfu aarin yikaka, eerun opin Φ800-1200mm. III. Awọn iṣoro ilana ati Awọn solusan

1. Isanra ti ko ni deede. Idi: Roller otutu Iyipo> ± 2°C. Solusan: Pipade-Loop Gbona Iṣakoso iwọn otutu Epo + Itutu-itutu Roller ti o wa nitosi.

2. Dada Gas. Fa: Insufficient Mixing Degassing. Solusan: Fọ aladapo inu (-0.08 MPa).

3. eti dojuijako. Idi: Itutu agbaiye / Ẹdọfu ti o pọju. Solusan: Din Itutu Itutu Iwaju-ipari ati Fi agbegbe itutu lọra kan kun.

4. Àpẹẹrẹ kú. Fa: Insufficient Embossing Roller Titẹ. Solusan: Mu Ipa Hydraulic pọ si 1.2 MPa ati Mọ Ilẹ Roller.

IV. Ore Ayika ati Awọn ilana Igbegasoke Iṣẹ

1. Rirọpo Amuduro Ọfẹ Asiwaju:

- Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Ṣe idanwo EN 14372 Iṣiwa;

2. Plasticizer Ọrẹ Ayika:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Din Ecotoxicity.

3. Atunlo Egbin:

- Fifọ awọn ajẹkù → Idapọ pẹlu ohun elo titun ni ipin ti ≤30% → Ti a lo ni iṣelọpọ Layer ipilẹ.

V. Calendering vs. Extrusion (Afiwe ohun elo)

Igbekale ọja: Ilẹ-ilẹ perforated isokan/Apapo ọpọ-Layer, Extrusion-Layer Multi-Layer (Layer-sooro Layer + Layer foomu)

Ibiti Sisanra: 1.5-4.0mm (Ipeye ± 0.1mm), 3.0-8.0mm (Ipese ± 0.3mm)

Ipari Ilẹ: Didan giga/Embossing titọ (afarawe ọkà igi), Matte/Sojurigindin ti o ni inira

Awọn ohun elo Aṣoju: Ilẹ-ilẹ perforated isokan ni awọn ile-iwosan ati awọn ile-iwosan, Ilẹ-ilẹ interlocking SPC fun awọn ile

Lakotan: Iye pataki ti ọna kika calendering wa ni “itọkasi giga” ati “iduroṣinṣin giga”

- Awọn anfani ilana:

- Iṣakoso iwọn otutu rola to tọ → Iṣirodipupo iyatọ sisanra <1.5%;

- In-line embossing and lamination → Ṣe aṣeyọri okuta / awọn ipa wiwo irin;

- Awọn ọja to wulo:

Ilẹ-ilẹ PVC perforated isokan pẹlu awọn ibeere iduroṣinṣin onisẹpo giga (gẹgẹbi jara Tarkett Omnisports);

- Awọn aṣayan igbesoke:

- Iṣakoso oye: Atunṣe rola ti o ni agbara agbara AI (awọn esi sisanra akoko gidi);

- Imularada Agbara: ooru egbin omi itutu ni a lo fun iṣaju ohun elo aise (fifipamọ agbara 30%).

> Akiyesi: Ni iṣelọpọ gangan, iwọn otutu calendering ati iyara rola yẹ ki o tunṣe ni ibamu si itusilẹ agbekalẹ (itọka yo MFI = 3-8g / 10min) lati yago fun ibajẹ ( atọka ofeefee ΔYI <2).

Akoko ifiweranṣẹ: Jul-30-2025